With amount of precision grinding machines and CNC center, St.Cera can meet the manufacture and technical requirements of various kinds of ceramic parts with complicated shape.

Length/Width (Max) : 1500mm Straightness : 0.005mm Surface finish(Min): Ra0.1

Thickness (Max) :100mm Roundness : 0.002mm Parallelism : 0.002mm

Out diameter (Max): 600mm Perpendicularity : 0.005mm Flatness : 0.003mm

Inner diameter (Min) : 0.2mm Concentricity : 0.01mm

Pressing is the most widely used forming process, which is especially suitable for ceramic products with kinds of small thicknesses.

Read More

Sintering is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction.

Read More

There are three kinds of grinding methods, such as Cylindrical Grinding, Outside Diameter Grinding and Inside Diameter Grinding.

Read More

Plane grinding is the most common of the grinding operations. This will also attain a desired surface for a functional purpose.

Read More

CNC milling has been regarded as one of the most widely used operations in machining.

Read More

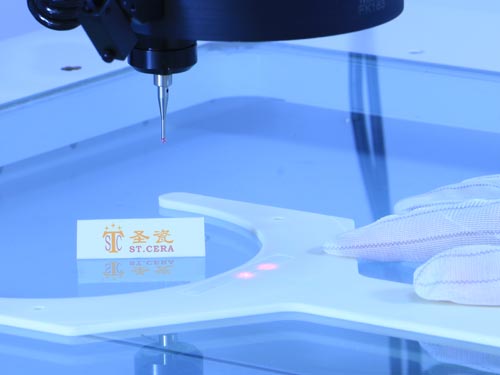

To ensure the manufactured products with no defect, all products have to pass the test by precision testing instrument before leaving factory.

Read More